Demystifying Embroidery Supplies (Machine Edition)

Demystifying Embroidery Supplies (Machine Edition)

So you’re ready to dive into the world of machine embroidery—welcome to the club! If you’ve ever peeked into a professional embroidery shop (or, you know, RM Custom Screen Printing), you’ve probably seen some high-tech machines humming away, turning digital designs into stitched masterpieces. But before you load up your favorite logo or artwork, let’s break down the essential supplies you’ll need for commercial machine embroidery.

So you’re ready to dive into the world of machine embroidery—welcome to the club! If you’ve ever peeked into a professional embroidery shop (or, you know, RM Custom Screen Printing), you’ve probably seen some high-tech machines humming away, turning digital designs into stitched masterpieces. But before you load up your favorite logo or artwork, let’s break down the essential supplies you’ll need for commercial machine embroidery.

Threads: The Colorful Heroes

Rayon: Known for its natural shine and smooth finish, rayon gives embroidery a softer, more classic look.

Polyester: Durable, vibrant, and fade-resistant, polyester is the go-to for most modern machine embroidery—especially for items that’ll see a lot of washing or outdoor use.

Want to go wild? Specialty threads (like metallic or glow-in-the-dark) are available, but we recommend starting with the basics for best results.

Needles: Small but Mighty

Yes, even machines need the right needle for the job!

Commercial embroidery machines use needles specifically designed for high speeds and heavy use.

Sizes: The most common size is 75/11 (great for most apparel), but thicker fabrics or specialty threads may require a different size.

Tips: Sharp-point needles are used for woven fabrics, while ballpoint needles are better for knits to prevent snags.

Pro tip: Needles wear out faster than you think—change them regularly for crisp, clean stitching.

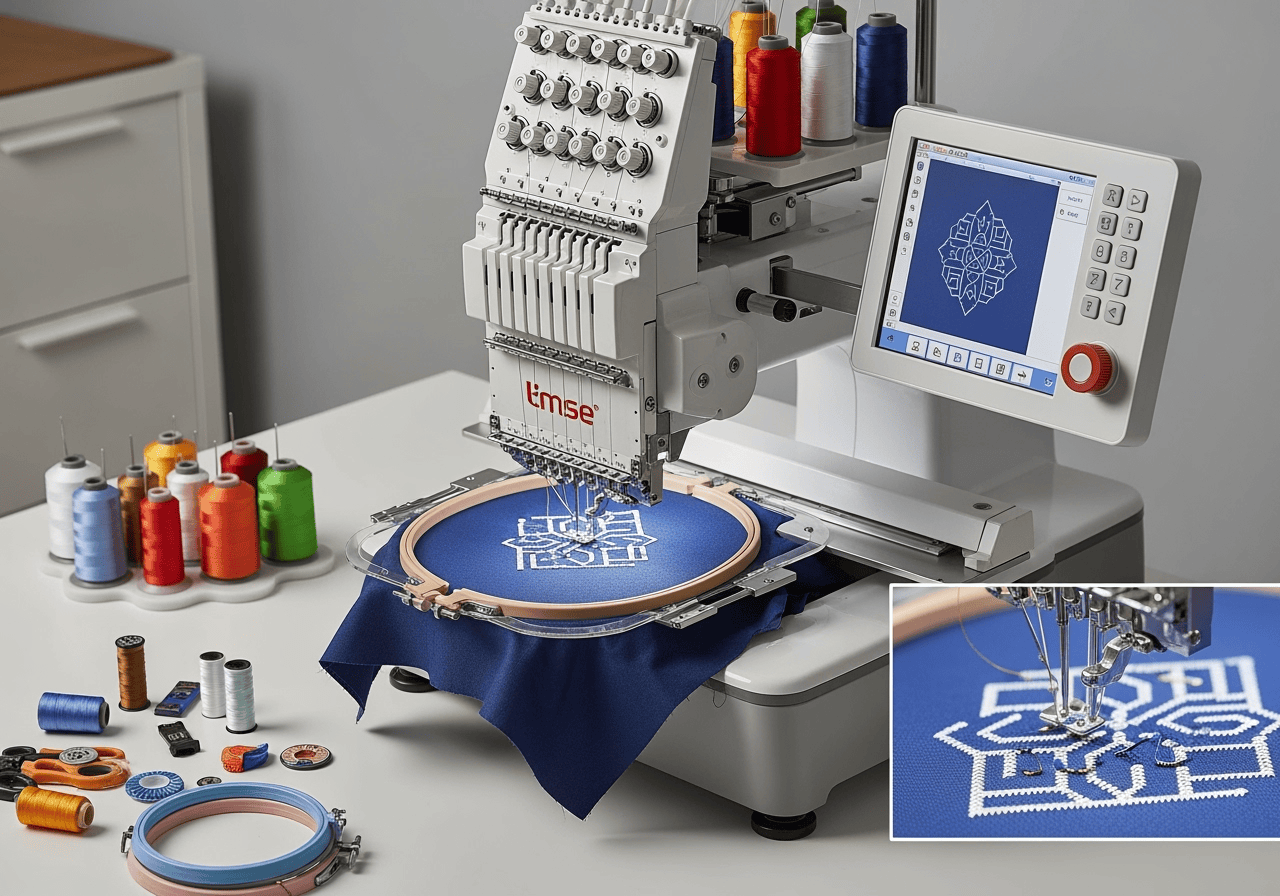

Hoops: Keeping It Tight

Machine embroidery hoops are a bit different from hand embroidery hoops.

Purpose: Hoops keep your fabric flat and secure while the machine works its magic.

Types: Commercial machines use sturdy plastic or metal hoops that “lock” into place. Some projects (like hats or sleeves) use special frames or clamps.

Sizes: Choose the hoop size that fits your design—too big, and the fabric can shift; too small, and your design won’t fit.

Bonus: A well-hooped project means fewer headaches and cleaner results!

The Process in Action

Here’s how it all comes together at RM Custom Screen Printing:

Design: Your artwork is digitized into a file the machine can read.

Setup: The right thread colors are loaded, the fabric is hooped, and the machine is prepped.

Stitching: The machine goes to work, switching threads and making thousands of stitches with precision.

Finishing: Once the design is done, we remove the hoop, trim threads, and inspect for quality—no loose ends here!

Final Thoughts

Machine embroidery is a blend of art and technology—and with the right tools, you’ll get pro-level results every time. Whether you’re customizing a polo for work or creating a one-of-a-kind gift, understanding your thread, needles, and hoops is the first step to embroidery greatness.

Ready to see your design come to life? Or got questions about which supplies are right for your next project? Drop a comment or reach out—we’re always happy to help you stitch up something awesome!